|

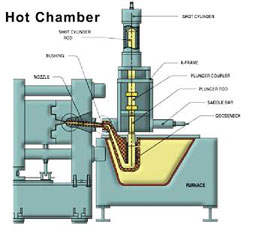

Die casting is the process of forcing molten metal under high pressure into mold cavities (which are machined into dies). Most die castings are made from non-ferrous metals, specifically zinc, copper, Aluminium, magnesium, lead, and tin based alloys, although ferrous metal die castings are possible. The die casting method is especially suited for applications where a large quantity of small to medium sized parts are needed with good detail, a fine surface quality and dimensional consistency. This level of versatility has placed die castings among the highest volume products made in the metalworking industry. Die casting was invented by Elisha K. Root, an inventor in the employ of Samuel W. Collins at the Collins axe-making factory in Canton, Connecticut in the 1830s. |

|

|

||||

|

Manufacturers of Zinc Die Cast Components

|

||||

|

|

||||

|

Stimela is a zinc die cast component manufacturer. We use high pressure die cast injection machines to produce our quality products. The products are made by either using single or multi cavity dies (moulds). Component weight ranges from 3 grams to 120 grams each. The main line is door keys and lock components. |

|

|

||

|

|

Copyright © www.stimelasa.co.za |

Updated: 19 April 2012 |

||